A Purpose-built Solution that Enables Secure Data Flows for the Oil & Gas Industry.

Owl’s hardware-enforced protocol filtering diode ensures safety, speed, and simplified compliance.

Get Started

Prevent Pipeline Disruptions

The oil and gas industry faces two major challenges when it comes to cybersecurity; protecting Operational Technology (OT) networks to prevent disruptions and outages and securely sharing data to monitor upstream, midstream, and downstream operations. Previous methods of securing OT networks, like relying on software-based firewalls, no longer suffice as threats like ransomware rise and become more sophisticated. While complete isolation of OT networks provides the highest level of security, it prevents the ability to get critical network data to those that need it. The only solution for truly protecting oil and gas OT networks and enabling secure data mobility is by implementing hardware-enforced data diode cybersecurity.

Securely Transfer Data To Those Who Need It

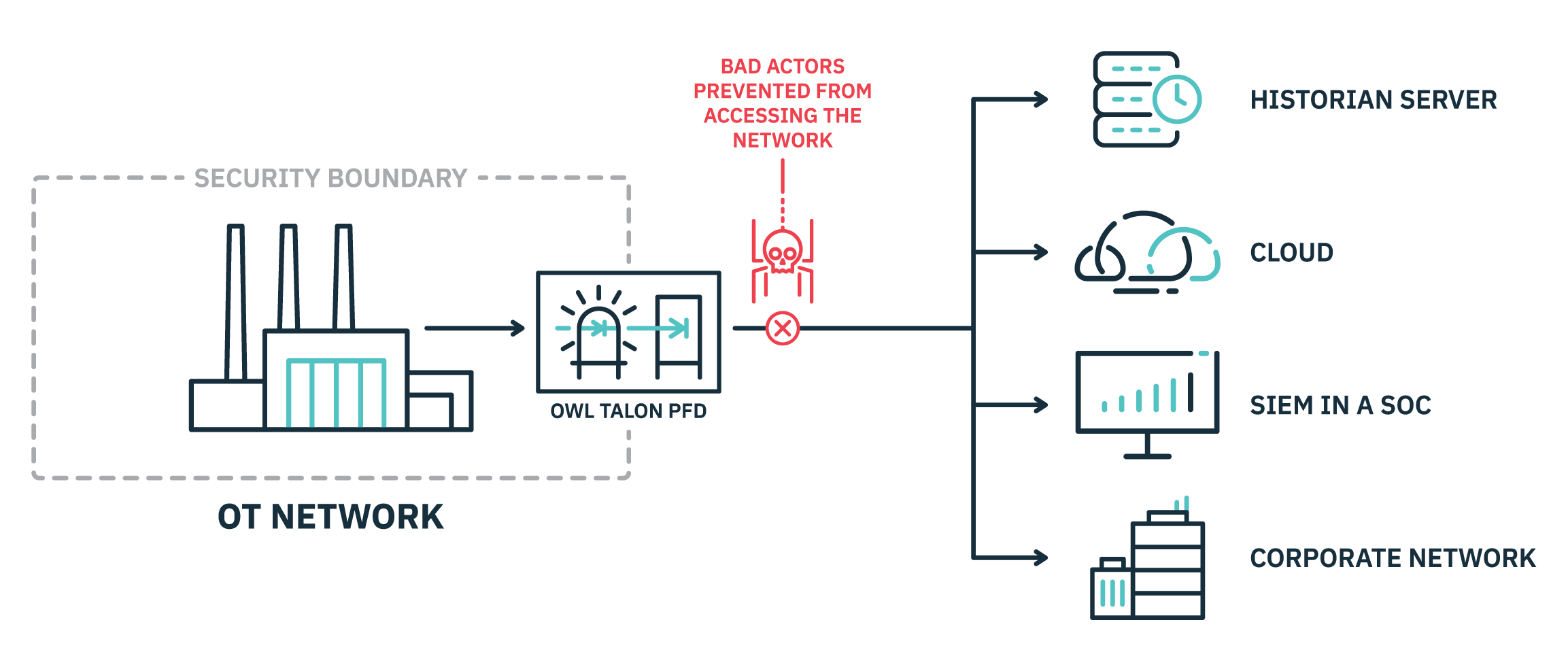

Hardware-enforced data diodes provide oil and gas organizations with a secure way to transfer critical data one-way out of OT networks to destinations like IT networks, historians, SIEM platforms, or the cloud, without introducing risk to OT networks. Owl data diodes are comprised of two communication cards that work as a pair. The first card is the “send” card and only has electronic components that allow it to send data one-way, with no ability to receive. The second card, the “receive” card, only has electronic components that allow it to receive data. This architecture only allows data to flow in one direction and it physically cannot travel the other way. Because a data diode is only physically capable of sending data one-way, a data diode creates a physical barrier or “air gap” between an OT network and a destination. This prevents data leakage, eliminates the threat of malware, and fully protects the sending network from external threats through the data diode’s network path.

Meeting Regulatory Compliance

Oil & gas organizations are held to a higher standard when it comes to the cybersecurity technologies they deploy compared to other critical infrastructure industries, resulting in the need to deploy solutions that adhere to compliance requirements and provide the highest level of security possible to prevent power delivery outages. Regulatory compliance standards that are relevant to the oil & gas industry are NRC, NERC-CIP, and NIST. Owl protocol filtering diodes map to these regulatory controls and are recommended as a best practice for securing OT networks, while enabling data mobility.

NRC

NRC: Regulatory Guide 5.71 – C.3.2.1 Security Defensive Architecture

NERC-CIP

NERC CIP-003-7: Attachment 1, Section 3.1

NERC CIP-005-6: R1 – Electronic Security Perimeter

NERC CIP-005-6: R2 – Remote Access Management

NERC-CIP-007-6: R1 – Ports and Services

NERC-CIP-007-6: R2 – Patch Management

NERC-CIP-007-6: R3 – Malicious Code Prevention

NERC-CIP-007-6: R4 – Security Event Monitoring

NERC-CIP-007-6: R5 – System Access Control

NERC-CIP-010-2: R2 – Configuration Monitoring

NIST

NIST 800-82, rev.2 – 5.1: Boundary Protection

NIST 800-82, rev.2 – 5.11: Unidirectional Gateways